Kickoff

Kickoff went smoothly this year! Alumni and mentors joined us bringing experience and fresh perspective. After the game animation, our kickoff crew came back from Plano ISD Academy and all our members dissected the game manual and presented each section. Members shared ideas freely and built off each other’s thoughts! Canes also sponsored us by providing sweet tea, keeping us fueled through long discussions!

We also added these 3D printed safety glasses holders in our workspace!

Mechanical

The first week after the game release moved fast, but our mechanical team moved faster. We began developing an intake system, experimenting with different wheel sizes and heights, and worked on storage designs to optimize ball handling. We finalized our intake subsystem prototype and began to CAD it. After finishing our intake, we started building a shooter prototype to test different angles and consistency.

In addition to robot prototypes, we worked on field construction in parallel, completing the base of the hub and starting work on the bump. The team drew inspiration from Ri3D teams and notable robots from previous years, and all rookie members contributed ideas, building on each other’s suggestions to improve designs. We also continued brainstorming concepts for climbing mechanisms, indexing systems, and other design improvements to prepare for full-scale testing. Adjacently, we continued our offseason project of a new robot cart. We added notches to join pieces, and finished the entire bottom deck. Catch us and our new robot cart at competition!

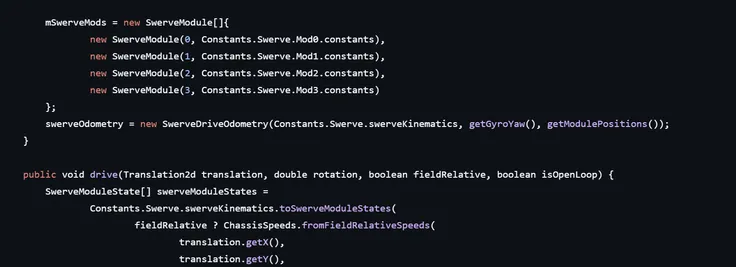

Programming

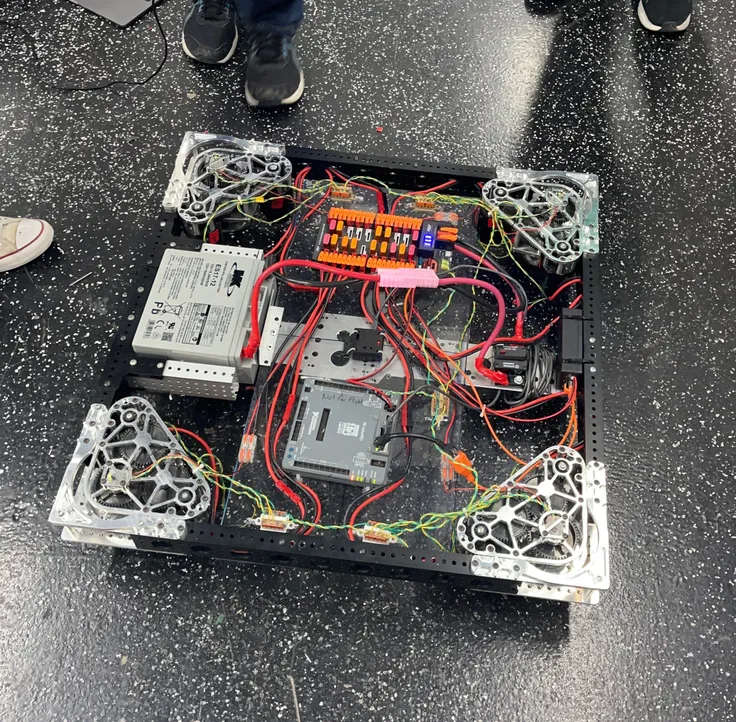

In the first week after kickoff, the programming sub-team has made significant headway on our robot chassis and is currently working on the Robot Rebuilt 2026 code project. Prior to the released game animation, we built a 30x30in chassis with our new SWFYT aluminum. However, the game manual has limitations on the chassis size, so we had to cut down to a 27.5x27.5 in. chassis. Adding to the chassis, we have completed the first iteration of the robot electrical board and have cleanly and successfully wired the swerve drive base and other related components (RoboRIO, NavX, etc.). This year has also been one of our cleanest in terms of wiring and electrical robustness. One example is our use of ferrule crimps on CAN wiring in order to greatly reduce the risk of CAN failures caused by wires coming loose from WAGO connectors.

For our codebase, we have set up the project, installed vendor dependencies, assigned CAN IDs to all devices, updated firmware, fixed CANCoder offsets, and tuned swerve feedforward values. Our plan moving forward is to finish wiring the vision subsystems and update any legacy code that relies on deprecated methods.